Ralat format e-mel

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Berita

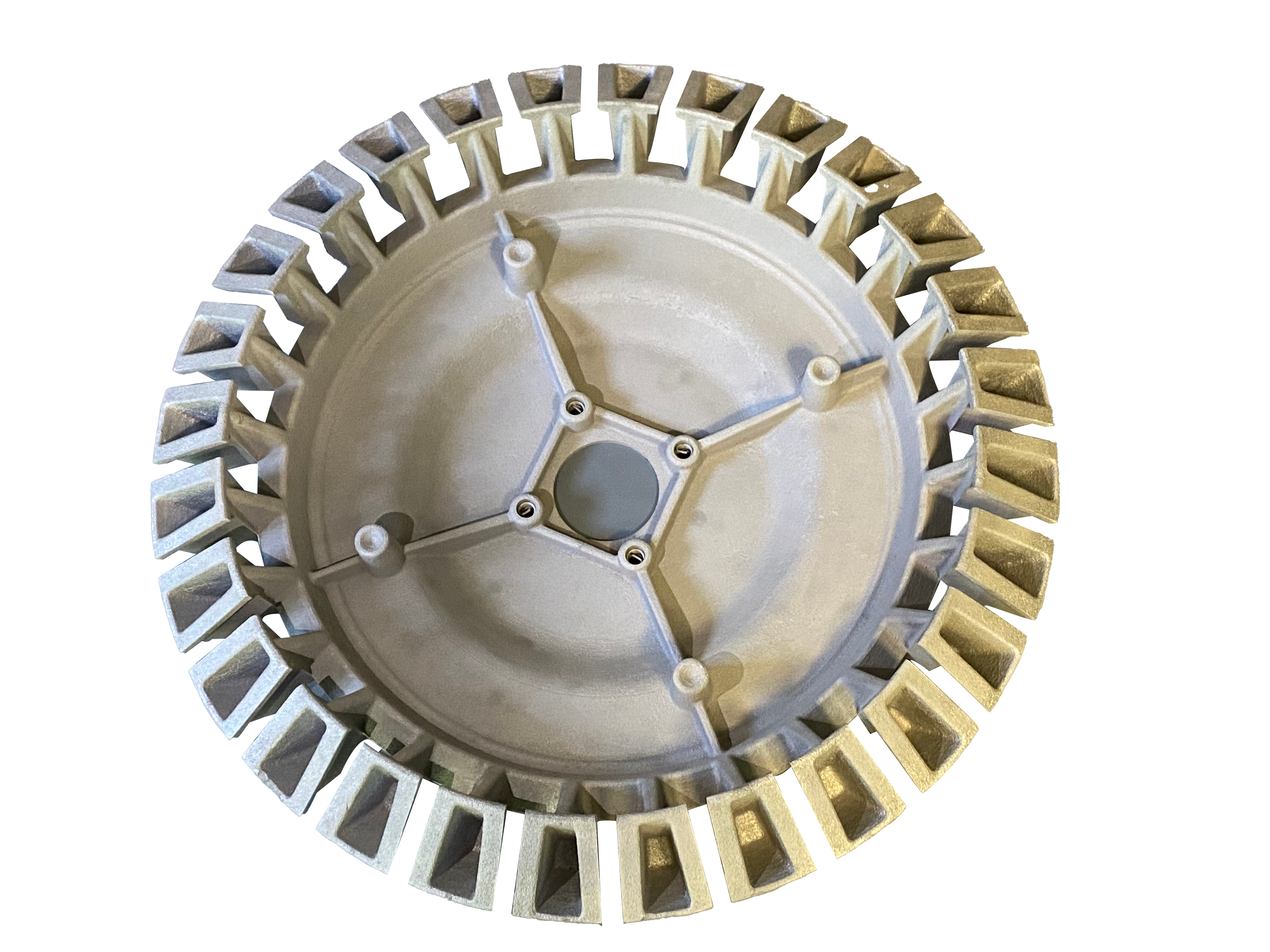

Sand Casting Process

There are mainly two casting methods: sand mold casting and special casting.

Sand casting is the most widely used casting method in practical production. Its main processes include 8: pattern manufacturing, modeling, core making, molding, smelting, pouring, sand removal, and inspection.

Pattern making

Shape and core box are required for modeling.

The pattern is used to form the outer contour of the casting; The core box is used to make sand cores to form the internal contour of castings. When the output is small, the shape and core box are usually made of wood, and when the output is large, metal or plastic is used.

When designing and manufacturing patterns and core boxes, the following five issues should be considered:

- Selection of parting surface: the parting surface is the surface where the two halves of the mold contact each other, and its selection should be appropriate;

- Determination of draft angle: generally, the wood formwork is 1~3 °, and the metal formwork is 0.5~1 °;

- Reserved shrinkage: considering the volume shrinkage of the casting during cooling and solidification, to ensure the size of the casting, the size of the pattern should be one shrinkage larger than the size of the casting;

- Reserved machining allowance: increase machining allowance for parts that need machining;

- Fillet treatment: to reduce cracks in castings and facilitate modeling and core making, the corners of patterns and core boxes are often made into fillets.

Molding

Molding is the most basic process of sand casting, which is usually divided into the manual molding and machine molding.

Manual molding: it's sand tightening and mold lifting processes are completed manually, with flexible operation and low cost. It is mainly used for single-piece and small-batch production.

Machine modeling: realize the mechanization of sand tightening and mold lifting, and often form a flow production line with mechanized sand treatment, pouring, and sand falling. High production efficiency and high cost. However, machine modeling cannot be carried out in three-box modeling, and at the same time, live blocks are avoided.

Core making

Core making is also divided into manual core making and machine core making.

Manual core making mainly uses a core box, which is most commonly used. Machine core making is used in mass production.

To improve the strength of core making, cast iron core bone or core bone made of iron wire will be placed in the sand core during core making; To improve the air permeability of the sand core, vent holes should be made in the sand core.

Zygotic type

After the molding and core making are finished, the molding is started.

Molding is the operation process of assembling the sand core, and upper and lower boxes. When closing the mold, first check whether the sand mold and sand core are intact and clean; Then install the sand core on the core base; After confirming the correct position of the sand core, cover the upper box and fasten the upper and lower boxes.

It should be noted that the sand mold and sand core should be dried before mold closing to increase the strength and permeability of the sand mold and sand core and reduce the gas that may be generated during pouring.

Pouring

After the metal is melted, pouring begins.

Pouring refers to the operation of injecting molten metal from the ladle into the mold. Attention should be paid to the following two points:

- The pouring temperature has a great influence on the quality of castings. Try to "discharge at high temperature and pour at low temperature" as much as possible. For castings with a simple shape, take a lower temperature, and for castings with complex or thin walls, take a higher pouring temperature.

- The pouring speed also has a great influence. In actual production, thin-walled castings should be poured quickly, and thick-walled castings should be poured according to the principle of slow fast slow.

During pouring, the channel through which the molten metal flows into the mold is called the pouring system. Generally, it includes sprue basin, sprue, and gate.

Sand removal

Generally, it includes sand falling, removal of pouring and riser, and surface cleaning.

Sanding: refers to the operation of separating castings from molding sand and sandboxes manually or mechanically. The temperature of the casting during sanding shall not be higher than 500 ℃ (premature removal will cause surface hardening or deformation and cracking).

Remove the pouring Riser: for brittle materials, hammering can be used to remove them. Before removal, saw the groove at the root of the pouring riser and then break it; For ductile materials, sawing and other methods can be used.

Surface cleaning refers to further cleaning the surface of the sticky sand. Now, vibration machines or sandblasting equipment are often used to clean the surface.

Inspection and repair

The quality inspection shall be carried out after casting cleaning.

The inspection items mainly include appearance, size, metallographic structure, mechanical properties, chemical composition, and internal defects. The most basic ones are appearance inspection and internal defect inspection.

Common casting defects are:

- Eyelets: such as pores, shrinkage cavities, sand holes, slag holes, etc.

- Surface defects: such as cold shut (incomplete fusion gap on the casting, smooth edge at the joint), sticking (there is a layer of sand particles on the casting surface that are difficult to remove), and sand inclusion (there is a layer of protruding metal flakes on the casting surface, and there is a layer of wet sand between the metal flakes and the casting).

- Unqualified shape and size: such as eccentric core, insufficient pouring (the casting is not fully poured, and the shape is incomplete), and wrong box.

- Cracks and others, such as unqualified chemical composition.

Casting repair methods mainly include:

- Gas welding and electric welding repair: used to repair cracks, pores, shrinkage cavities, cold shuts, sand holes, etc.

- Metal spraying: spray a layer of metal on the defect.

- Molten metal remelting, etc.