Ralat format e-mel

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Berita

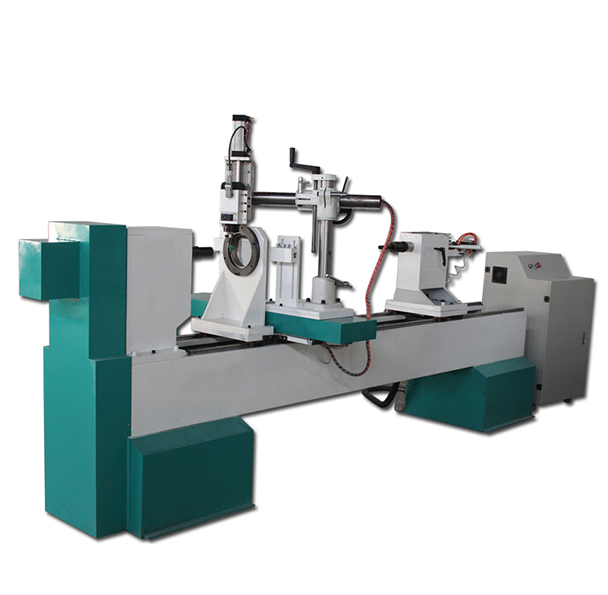

Inventory of the Processing Characteristics of CNC Wood Lathes!

What are the processing characteristics of CNC wood lathes? Now let's have a brief look.

It has strong adaptability to processing objects.

When changing the processing parts on the CNC wood lathe, the new parts can be processed only by reprogramming. Unlike traditional wood lathes, there is no need to manufacture and replace many cutting tools, fixtures, and measuring tools, and there is no need to readjust the lathe. Therefore, CNC wood lathes can quickly change from processing one part to processing another part, which provides convenience for the trial production of single pieces, small batches, and new products, which not only shortens the production preparation cycle but also saves a lot of cutting tool costs.

High machining accuracy.

CNC wood lathes are processed by instructions given in the digital form. At present, the pulse equivalent of CNC wood equipment can generally reach 0.001mm, and the reverse clearance and pitch error of the feed transmission chain can be compensated by CNC equipment. Therefore, a CNC wood lathe can achieve high machining accuracy and quality stability, which is determined by the necessary measures taken in the structural design of the CNC lathe and the characteristics of electromechanical integration. Firstly, the ball screw nut structure and various clearance elimination structures are used to reduce the mechanical transmission error as much as possible. Secondly, the software compensation technology is used to further reduce mechanical error. Thirdly, the influence of human factors on machining accuracy is reduced through program control processing. These measures not only ensure the high machining accuracy of the CNC wood lathe but also ensure the stability of high machining quality.

High production efficiency.

The time required for processing parts includes maneuvering time and auxiliary time. CNC lathes can effectively reduce these two parts of time, so the processing productivity is much higher than that of general wood lathes. The spindle speed and feed speed range of CNC lathes are larger than that of ordinary lathes, and the appropriate cutting amount can be selected for each process. At the same time, the good structural rigidity also allows the CNC wood lathe to cut with a large cutting amount, which effectively saves maneuvering time. The acceleration and deceleration measures are adopted for the rapid movement and positioning of the moving parts of the CNC lathe. Therefore, a higher idle travel speed is selected. The time spent on fast forward, fast backward, and positioning is much less than that of the ordinary lathe. The machining accuracy of the CNC wood lathe is relatively stable, Generally, only the first article inspection and sampling inspection of key dimensions between processes are carried out, which reduces the time of shutdown inspection. When using the CNC wood lathe with a tool magazine and automatic tool change device, the continuous processing of multiple processes is realized on one lathe, which reduces the turnover time of semi-finished products and improves production efficiency more obviously.

Good economic benefits.

When machining parts with a CNC wood lathe, the equipment cost allocated to each part is relatively expensive. However, in the case of single-piece small batch production, it can save the cost of process equipment, auxiliary production hours, production management costs, and reduce the scrap rate, so it can obtain good economic benefits.

The high degree of automation.

The CNC lathe automatically processes parts according to the pre-programmed program. In addition to operating the panel, loading and unloading parts, measuring the middle of key processes, and observing the movement of the wood lathe, the lathe action is automatically and continuously completed until the processing is completed. There is no need for heavy repetitive manual operation, the labor intensity and tension are greatly reduced, and the working conditions are correspondingly improved.

For more information about cnc lathe machine for wood, cnc wood lathe price, small cnc wood lathe, plz feel free to contact us.